1.

Introduction

Over

the last ten years we have been witnessing a transformation in the structure

and daily operations of large and small enterprises because of the drive to

lower costs, leverage the Internet for business operations, and integrate

better with their supply chains. Increasingly, enterprises are dependent on their supply and

value chains to build products and deliver services respectively. This has a profound impact as the streamlined

flow of information and services in the supply and demand chains is crucial to

manufacturers and enterprises wishing to capture the product feedback needed to

improve product quality and increase customer satisfaction. For example, in the

automotive industry, information disconnection in the demand chain is causing slower

product feedback, rising warranty costs and declining customer satisfaction in

spite of the advances in vehicle technology. Sensing and alert management in such demand

chains can provide accurate and faster feedback, improve quality and reduce

costs. In the following, we present the

motivation for scalable sensing and alert management.

Rising

warranty costs: It is estimated that in the US alone, the warranty costs in the automotive industry are

around 3% of the OEMs (manufacturers) revenue, and the total costs for 2003 are

estimated at 12 Billion USD[i],

and rising. The same issues are being grappled with in the Electronics,

Aerospace and Heavy Engineering industries. Manufacturers are extremely concerned about

the rising warranty costs, and are determined to reduce them as much as

possible through sensing product information (e.g., vehicles) and their status

in real time.

Lack of visibility into operations: Most enterprises

do not have deep visibility (at a fine grained level), controllable operational

models and flexible and easily modifiable business operations. With sensors and

actuators the right capabilities for monitoring operational performance, integration

and control can be enabled for businesses to sense and adapt their daily

operations in a timely manner. In the

world of industrial sensors, the model of top-down design becomes critical as

the right sensing of the operations can provide crucial information for

optimizing business operations. The business metrics for enterprise operations can

include improving the current cycle times of the core business processes in

manufacturing, production, parts, inventory and sales. Shrinking the cycle times necessitates deeper

and better visibility in the enterprise operations. In

this paper, we discuss various business scenarios, challenges and technology

components that can enable such monitoring and evaluation in a scalable

fashion.

Several

papers and articles in the literature ([1], [2], [3], [4], and [5]) present novel

event stream processing work. However, they

have primarily focused on ad hoc communication domains or domain agnostic

systems, and very few have focused on using semantics for event processing. The fundamental difference in our work is

combining domain knowledge structures with sensor information to extract

meaningful information in order to generate real alerts and take actions

through complex decision processes or activate additional monitoring processes.

1.1. Business Metrics and Challenges

In order to enable monitoring of business

operations, specific business metrics need to be defined for capturing the

state of the business operations, current performance and trends. Tracking these metrics enables gathering of intelligence

and predicting future trends in order to make timely decisions. For example, metrics are defined for managing

the life-cycle of products from the production phase to the delivery and

service phases. The following are typical examples of business metrics: a) Production and product life-cycle process

times; b) Down time of assets in production and assembly lines; and c) Cost of

monitoring production processes through automation. The challenging problems include identifying

the metrics (assets or processes), sensing the data for the metrics in a

scalable fashion, controlling the sampling rate dynamically, and evaluating the

data to extract critical alert information.

1.2. Contributions

Summary

of the Alert-Event System: In this paper, we describe a unified semantic

event stream system that continuously monitors diverse data sources and generates

alerts based on domain specific rules. This system can enable manufacturers to

closely monitor critical business events (reducing surprises) and gather

business intelligence from information such as product failures, warranty

intelligence, field events, sales transactions, asset performance and others. Our solution is currently undergoing field

trials and pilot deployments. This paper

discusses the system design, methodology, reliability and scalability. A mathematical foundation is being worked on, but

is beyond the scope of this paper.

2. Business

Scenarios

In

this section, we present two business processes and then describe the business

and technical challenges.

2.1. Production,

Engineering and Service

Production

processes and asset-management: Enterprises

are investing in sensor systems to enable the monitoring of the production

processes, production assets and product lifecycles in the factory

environment. The deployed sensors in the

production environment capture daily production data and quality information in

near real-time for the production engineers and specialists to keep a close

watch on the manufacturing processes and assets involved in the process (e.g.,

robots on an assembly line).

Industrial

Sector Demand Chain: In the Automotive Sector,

manufacturers must manage rich relationships with dealers, fleets, and

independent repair shops to support vehicle service lifecycles and build

aftermarket revenue streams. Optimizing

these aftermarket relationships requires OEMs to effectively support a wide

range of critical business activities including real-time sensing of inventory

replenishment, logistics, parts tracking, product behavior, retail performance

management and others.

Real-time integration of diverse sensors and data types: Integration of a multitude of events and data from various sensors in

various formats is a complex challenge. Sensors of various kinds are being

deployed at every operational manufacturing site. These sensors are built by

third-party vendors who have custom ways of sensing, sampling and generating

the events. The data rates could range from 1-50 megabytes per second. The monitoring, integration, analysis and

distribution of event information based on the data are critical for enterprises

to streamline their manufacturing processes.

Programmability of controllers and actuators: Current pervasive systems are focused towards light-weight middleware

layers over mobile devices with programming frameworks such as MIDPs, SMF, OSGi, J2ME and others. For a service oriented model, where sensor

controllers and actuators offer services to higher level applications access

(e.g., sampling rate), new models of programmability with messaging controller

interfaces (e.g., Web Services) are needed.

Service-Oriented

abstraction: With heterogeneity of various applications,

information sources, sensors, and sensor controllers, there is a need to

abstract away the underlying sensor components and interfaces into a collection

of services for higher level applications to use and configure. Each device controller can be defined by a

service interface to enable regional or local computing servers to access and

integrate with the controller.

4. Event Stream Processor Overview

At the center of the system solution is an

Event Stream Processor which handles all events, ultimately deciding on the

actions that need to be taken. Every kind of message coming from external

systems, sensors and devices are treated as events. When running, the Event Stream

Processor steps through following for each event: a) Event message receipt; b) Event

transformation; c) Metric calculation; d) Metric evaluation; and e) Action invocation. The first 2 steps are performed at a message adapter layer.

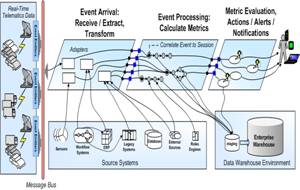

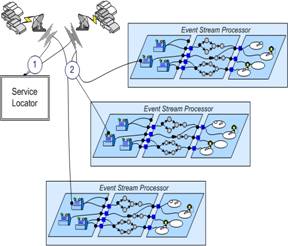

Figure 1.

Flow of Event Stream Processing

Figure 1.

Flow of Event Stream Processing

4.1. Event

Message Receipt

The Event Stream

Processor has adapters for receiving messages. Adapters determine the transport

mechanism for the group of senders (HTTP, JMS, etc). We have created adapters

which have web services that can be called from clients. We also have adapters

which can pull events by polling a potential event source. Here web services

can be used to.

4.2. Event

Message Transformation

Each adapter is

capable of handling different formats of event messages. During transformation

the messages are converted into a common format. Many different transformations

are supported. The preferred method of transformation is via a web service

call. The actual transformation can be done via any of the commonly accepted

transformation techniques including XSLT, translator packages, and straight

Java code.

4.3. Metric

Calculation

Metrics are

calculated measures based on incoming events. Metric calculations can go beyond

the scope of events, potentially accessing other systems for additional data

input or for additional calculations. Rules engine integration falls into the

calculation category. Computations can range from mathematical calculations to

text analytics including syntax and semantic analysis. For the automotive

industry, we have created metrics for: a) Fleet management or individual

vehicle monitoring, e.g., “running average of vehicle speed”; b) Complaint

management, e.g., “warranty claim symptom”; and c) Class of vehicle

performance, e.g., “percentage of vehicles within a class (Make, Model, Year,

Trim combination) with warranty claims on a particular subcomponent.”[ii]

Metrics can be

processed on both structured and unstructured information. Telematics systems

in automobiles collect many (anywhere from thirty to over 100) different

parameters from vehicles. The telematics systems take snapshots of how the

vehicle is being used and is performing. Values such as engine speed, vehicle

speed, and tire pressure are collected multiple times per second. These values

are well-structured real numbers. Metrics based on telematics data can be as

simple as the value itself, such as “tire pressure” or can be calculations

based on current and previous values, such as “running average of the vehicle

speed to engine speed ratio.” Calculations can include multiple different types

of values, common with ratios, or even values from external sources.

Unstructured

information may come in on events which contain text fields. For instance,

automobile warranty claims come from dealers containing service technician

write-ups. The text fields contain brief descriptions of the symptom and cause

of a problem as well as the action taken. Each of symptom, cause and action can

be metrics that are “calculated.” In this case the calculation consists of

syntactic and semantic analysis of the text using glossaries of categorized

terms, abbreviations, and common misspellings.

4.4. Metric

Evaluation

Prior to the Event Stream

Processor being run, an expert (or a group of experts) with a great knowledge

of the data, expected event arrivals, and normal overall system behavior

creates rules based on the metrics. These rules are used in both the Metric

Calculation and Metric Evaluation phases of the processing. An example of such

a rule on (structured) telemetric data in written form is “the twenty minute

running average of vehicle speed should not exceed 75 miles per hour.” Rules

are actually stored in XML form. An example of a rule on the (unstructured)

text of warranty claims using metrics described previously could be “there

should never be a warranty claim where the symptom was fire” which will enable

a quality analyst to be immediately alerted if such an unfortunate incident

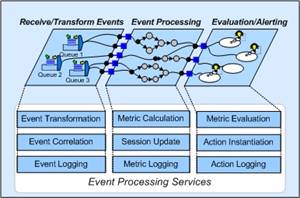

should occur. Figure 2

shows each of the steps taken by the Event Stream Processor. Each step has a

well-defined interface that is implemented by a local web service. Using such a

Service Oriented Architecture allows easy modification of the processor’s

behavior through simple plug-and-play.

Figure

2. Services

Oriented Architecture of the Event Stream Processor

Upon arrival,

events are passed to the Event

Transformation Service to be converted into the standard format used by the

rest of the event processor. Based on the incoming event, the Event Correlation Service retrieves a

list of metrics which need to get calculated. For a metric involving past

values, the service also retrieves the relevant session. The values contained in the event are then used in calls to the Metric Calculation Service. The Event

Stream Processor invokes the Session

Update Service to update the session to ensure the current event is

included in future metric calculations. The Metric

Evaluation Service determines what actions if any need to be taken based on

the newly calculated metric. These actions are taken with calls to the Actions Instantiation Service.

5. Scalability

Scalability is a

key design point for the Event Stream Processor. The ability to handle large

numbers of events has become paramount in the new world of sensors and

actuators. For scalability, we need to look at the Event Stream Processor as

well as the systems it uses. For the processor itself, there are two issues

preventing simple replication of the server to allow any number of instances of

it working in parallel, i.e., direct scalability. The preventative issues are

session management and event listening.

The Event Stream

Processor continuously calculates metrics, which get updated as events arrive.

Calculations of metrics often depend on having sessions. That is, we need to

store information about past events to calculate metrics based on new incoming

events. A common example is with the calculation of running averages. Consider

the metric of a running average of engine speed, a common value supplied by telemetry,

for a particular vehicle. If the running average is over a ten minute period,

then all data coming in over the last 10 minutes must be stored. All the data

for a particular vehicle is needed together in the session to be able to do the

calculation. As each new triplet of vehicle, timestamp, and engine speed

arrives for a particular vehicle:

- The session for the

engine speeds for that vehicle is retrieved.

- Data no longer needed (older

than ten minutes in this case) is removed from the session.

- The incoming timestamp

and value are stored. (Steps 2 and 3 can be implemented with a circular

array of session data.)

- The running average

metric is calculated.

- Rules are applied to

the calculated metric to determine if a warning needs to be indicated.

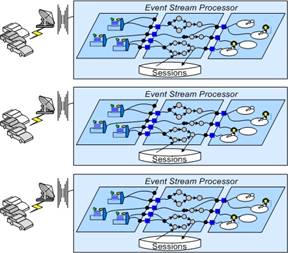

Figure

3. Assigning

Event Creators with Their Own Processors with Local Sessions

Scalability can

only be enabled by ensuring the current version of the session is available at the

instance processing the event. One option for solving this problem is to have a

common store for the sessions. As shown in Figure 4, the sessions can be stored

in a Database Management System or a data grid. Each instance of the Event

Stream Processor would retrieve and update the sessions as needed. Both

database managers and data grids are often wrapped in web services. Another

option for ensuring session availability, shown in Figure 3, is to assign each

session to a particular Event Stream Processor instance. Sessions can then be

stored and managed locally by each processor.

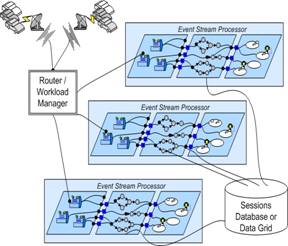

Figure 4. Using a Router

to Pass Events to Processors with Shared Sessions

Message receipt

remains separate from event processing allowing multiple nodes to handle the

processing. In one instantiation of our system, we route incoming events based

on the session to which they belong. Each event processing node handles the

events for a group of sessions. There are two main factors in deciding how to

partition the sessions across the event processing nodes:

- Can we separate the

sessions in a way so that all the metric calculation can be done locally?

That is, can the data existing within the Event Stream Processor be

collocated within nodes so that metric calculation can be done locally?

- Can we separate the

sessions so they are split up so that messages of the same type go to

different event processing nodes? Messages are typically skewed by type.

For instance, if metric calculations are mostly at the vehicle level,

“change in transmission gear” events are much more common than “engine on”

messages. Routing messages by vehicle will avoid workload problems caused

by the difference in the volume of messages by message type.[iii]

6. Routing

There are two

methods for handling the message routing:

1.

Using a conventional message router

2.

Assigning target web services for each of the different

sessions

Message routers

are well understood, but we’ll explain further on the use of web services. Each

different session can have its own web service. Each event creator can then be

assigned a specific web service to call based on the session needed for its

events. This type of mapping of event to sessions only works when sessions are

only needed at the creator granularity. The metrics being calculated dictate

the granularity. As long as a group of sessions rely only a specific set of

event creators, those creators can use the same web service.

Figure 5.

Using a Service Locator to Allow Event Creators to Send to a Processor

A more elaborate scheme to allow creators to send different types of events to

different nodes consists of two steps. Prior

to sending the event, a service is called to determine where to send the event.

This routing decision can be based on the message itself. This mechanism pushes

some of the routing processing onto the event creator. This approach has been

described extensively in The Integrated Building Design Environment by Fenves

et al [6]. A key ability of the Event

Stream Processor is how at each step in its event processing, it can integrate

with external systems. In one particular instance we integrate with a semantic

text analytics engine. Every time a warranty claim event is processed, it is

passed along to the semantic text analytics engine to pull out symptoms,

causes, and actions from text entered by the service technician at the

automotive dealership. The integration can be done synchronously or

asynchronously as shown in the figures below.

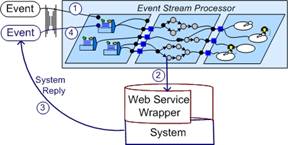

Figure 6. Synchronous Integration of External System

With synchronous integration, as shown

in Figure 6, during event processing the call to the external system is made

and the processor thread making the call awaits a response. Choosing

synchronous integration makes most sense when integrating with external systems

that respond quickly relative the needed response time.

The asynchronous integration shown in

Figure 7 allows processing to continue prior to getting the result of the

call. When the processing of the call is

completed, the system creates a new event which allows processing to continue.

Figure 7.

Asynchronous Integration with an External System

7. Conclusion

In

this paper, we described a novel unified semantic event stream processing system

for general critical alerts that enhances manufacturer process efficiency in quality,

service, and warranty management. This

system improves visibility into critical alerts and reduces surprises on

warranty costs. It allows business early

access to information and trends. Our alert

and event system is undergoing field trials. A version of the solution has

already been deployed and functional on real industrial data. The system is written in Java with XML and Web

Services as the support for semantic data structures, rules, configuration and

evaluation. The performance has been

excellent on real-time information streams.

Flexibility allows multiple deployment scenarios enabling the system to

be optimized for various event evaluation mechanisms. Various techniques are deployed to allow for

scalability with the metric types and data patterns determining which technique

is to be used. Further validation on the

scalability and routing is being done in real pilots and engagements.

References

[1]

Daniel J Abadi et.

al., The Design of the Borealis Stream Processing

Engine, Second Biennial Conference on Innovative Data Systems Research

(CIDR 2005), Asilomar, CA, January 2005.

[2]

C.

McGregor and Josef Schiefer, A

Web-Service based framework for analyzing and measuring business performance,

Information Systems and E-Business Management, Volume 2, Issue 1, Apr 2004, pp.

89-110.

[3]

Tivoli

Risk Manager, Event Correlation Engine, 2003. http://www.ibm.com/tivoli.

[4]

David

Luckham and Mark Palmer, Separating the

Wheat from the Chaff, RFID Journal, 2004.

[5]

Rajit

Manohar and K. Mani Chandy, Dataflow Networks for Event Stream Processing,

16th IASTED International Conference on Parallel and Distributed Computing and

Systems, November 2004.

[6]

S.

Fenves, U. Flemming, C. Hendrickson, M. Maher, R. Quadrel, M. Terk, and R.

Woodbury. Concurrent Computer-Integrated Building Design.

Prentice-Hall, Inc., Englewood Cliffs, New Jersey, 07632, 1998.